DENTALL

We named this product DENTALL by combining the Japanese words for electricity (“den”) and conductivity (“tall”) because of its electrical conductivity characteristics.

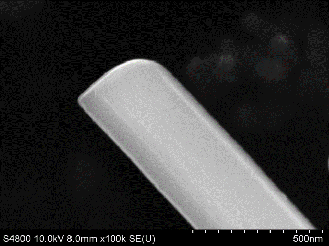

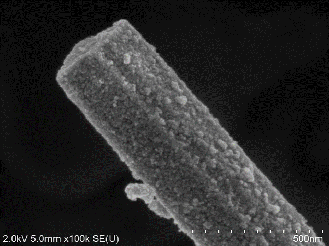

We use a ceramic synthesis technique to produce potassium titanate fibers and a surface conductivity technique to coat the ceramic surface with a uniform conductive layer.

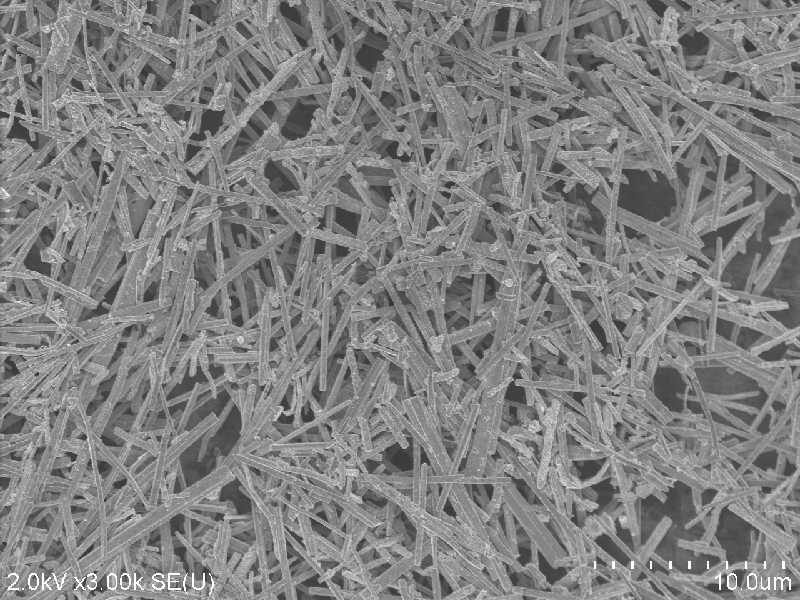

DENTALL is a white conductive filler that is uniformly coated with nano-order transparent electrically conductive layers on the surface of inductors made of white potassium titanate fibers (TISMO).

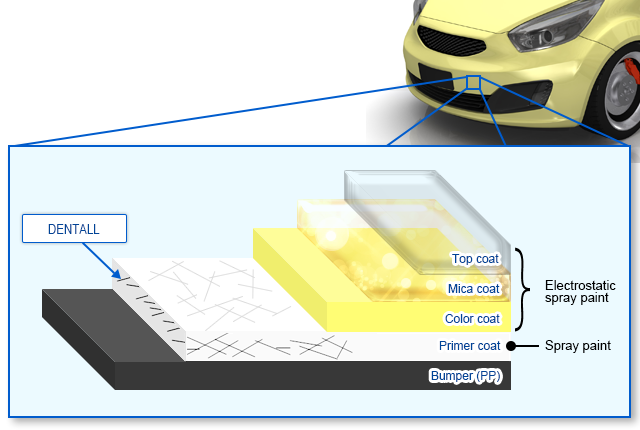

By adding DENTALL to various paints, adhesives, resins, or other materials, our customers can provide conductivity without compromising the whiteness of these materials.

Advantages

White color:

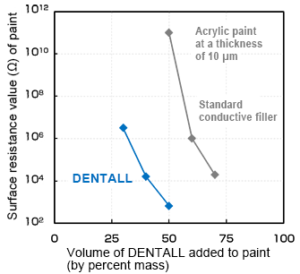

It demonstrates a higher degree of whiteness than conductive materials with similar resistances.

Lower added volume:

Because it creates a conductive network in the form of fibers, conductivity can be provided even with a small volume of filler.

General Properties

| Grade | WK-200B | WK-500 | WK-500B |

|---|---|---|---|

| Chemical composition | K2O・6TiO2 / SnO2 (Sb) | TiO2 / SnO2 (Sb) | TiO2 / SnO2 (Sb) |

| Appearance | White gray powder | Light gray powder | Light gray powder |

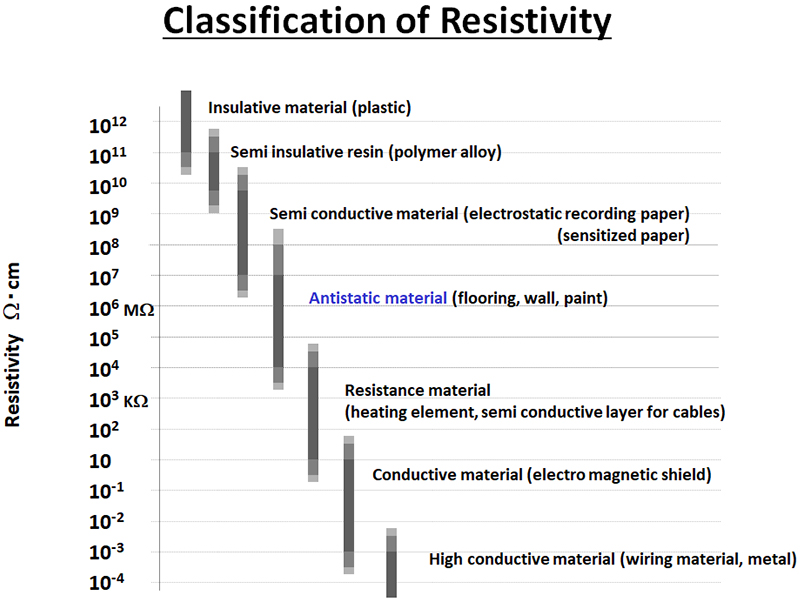

| Electrical resistance1)(Ω・cm) | 10-0~1 | 101~2 | 101~2 |

| Whiteness (L value) | >60 | >73 | >76 |

| Average fiber length (µm) | 10~20 | 5~15 | 5~15 |

| True density (g/cm3) | 4.3~4.6 | 3.5~4.0 | 3.5~4.0 |

| Bulk density (g/cm3) | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 |

| Water content (mass%) | <1 | <2 | <2 |

| pH (dispersed in water) | 4~8 | 2~4 | 6~9 |

| Specific surface area2)(m2/g) | 5~15 | 15~25 | 10~25 |

Applications

| Functions | Applications | >WK-200B | WK-500 | >WK-500B | |

|---|---|---|---|---|---|

| Conductivity | Primer for electrostatic spraying | (Solvent-based) | ○ | ◎ | ○ |

| (Water-based) | ○ | ○ | ◎ | ||

| Paint for aircraft components | ○ | ◎ | ○ | ||

| Preventing electrification | Conductive paint for building materials | (Solvent-based) | ○ | ◎ | ○ |

| (Water-based) | ○ | ○ | ◎ | ||

| Dust resistance | Silicon wafer baskets | ○ | △ | △ | |

| IC inspection trays | ○ | △ | △ | ||